|

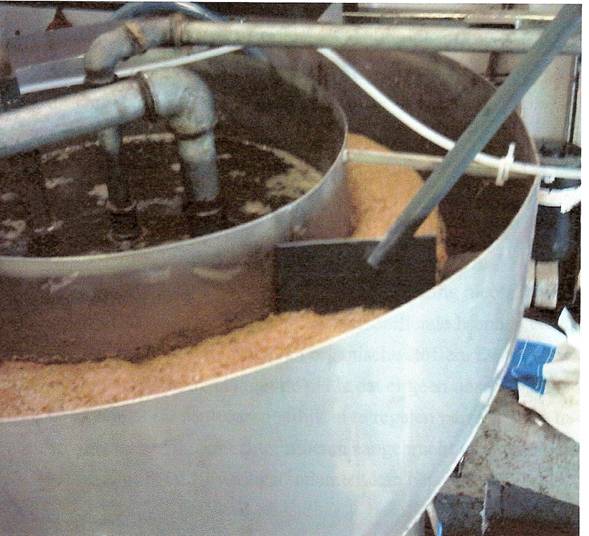

This pilot installation may test whether dissolved air flotation is a suitable water treatement step. In the long run the aim is to create, optimalize and automatize this small pilot installation as drinking water production station (+/- 500 L/h) and general as automatic process parameter optimalizer. This pilot installation is then able to test and determine automatically the optimal characteristic parameters of a flotation process.

This is the installation setted up at the VMW (Flemish Water Supply company).

Dissolved air flotation is a technology which is used to separate small particles which are dissolved in the water.

By adding small airbubbles (saturated water) to the polluted water the airbubbles will put themself arround the particles (pollution) and will bring the particles to the surface where it can be separated from the clean water. The slugde (all the particles together) can be separated at the surface.

The saturated water is clean water which is injected in the polluted water, the amount of clean water is called the recycle rate. The recycle rate is an expencieve factor in the flotation process and should be optimalized. But also retention time, amount of floculant, coagulant, energy of the static mixer, etc. are parameters to be determined and optimalized.

Pneumatic Adjustable Nozzle (PAN) for flotation installations

Thanks to co-promotor ir. Jan Cromphout from the Flemish water supply some important modifications could be executed.

This is the pneumatic adjustable nozzle added on the installation:

The nozzle test: the water is full of small airbubbles:

The results of one day testing: download table

Advise for the future:

Some few more modifications should be executed and try again.

|